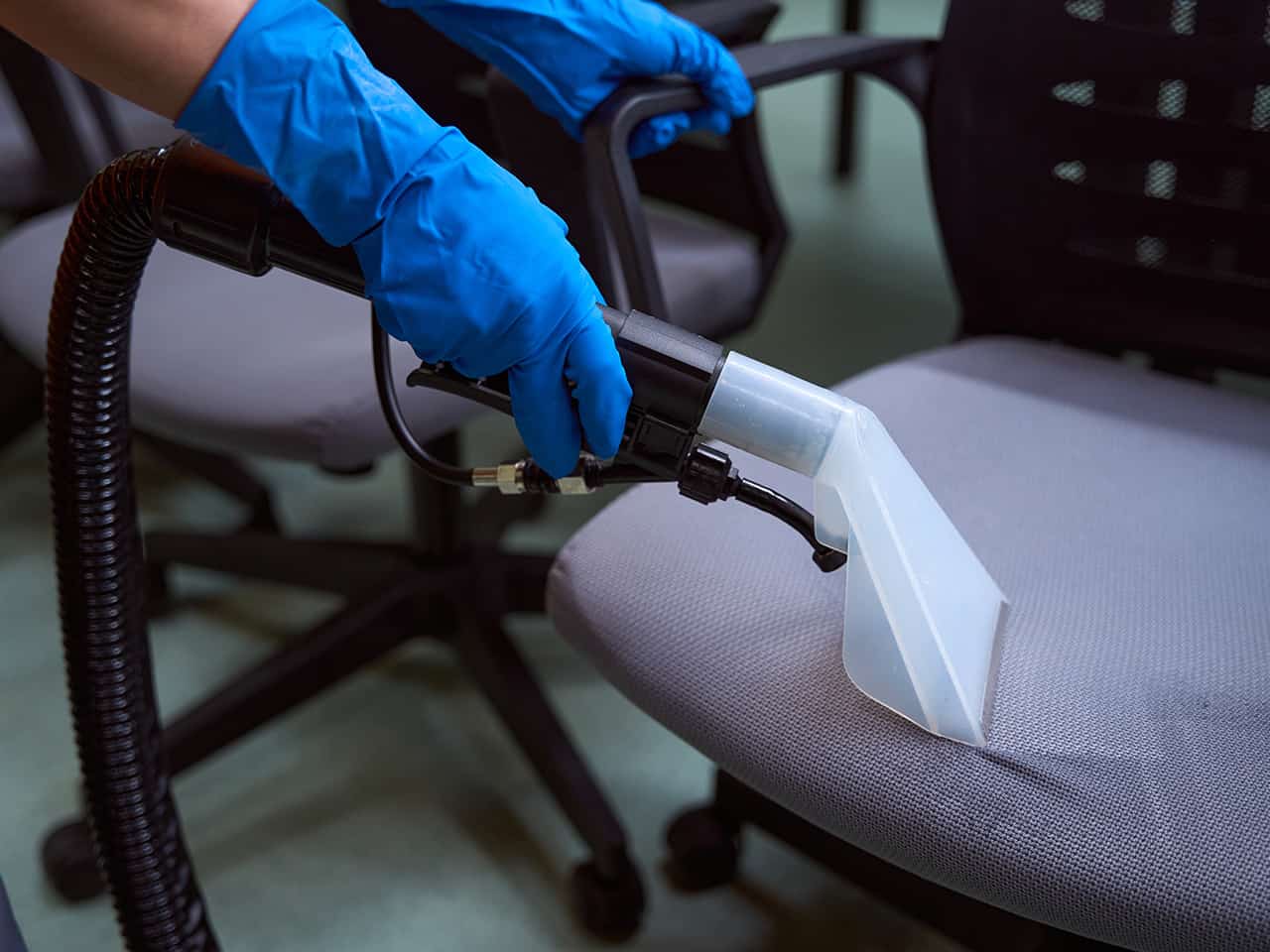

XL North’s Suggested Procedures for Cleaning Upholstery PDF is an in-depth guide providing a detailed walkthrough for cleaning a variety of commercial upholstered items with different tools and cleaning products. Covering every step from pre-assessment and setup to cleaning techniques and drying procedures, our XLN guide serves as a thorough resource.

Suggested Procedures

Suggested Procedures: Dealing with Ice Melt on Resilient Floors

Winter weather brings more than just snow—it leaves behind tough ice melt residues that can damage resilient flooring, dull finishes, and make cleaning more difficult. XL North’s Suggested Procedures for Dealing with Ice Melt on Resilient Floors provides a step-by-step approach to effectively remove these residues, maintain your floors, and prevent long-term damage. In this […]

Tags

Suggested Procedures

Suggested Procedures: Using UV Light to Remove Dispersed Dye Stains

Stubborn organic stains like turmeric and mustard don’t have to be permanent.XL North’s Suggested Procedures for Using UV Light to Remove Dispersed Dye Stains outlines a proven method for trained professionals to effectively treat tough stains on nylon carpet. Submit the form to download the guide and add this specialized approach to your toolkit.

Tags

The Flooring Contractor & Initial Maintenance

In this article, we’ll consider the many advantages and benefits of using a professional floor maintenance company to perform initial maintenance in a newly installed or remodeled flooring project. Protecting the Flooring Contract with Initial Maintenance The flooring contractor’s sales person spends a great deal of time working with the customer selecting the perfect flooring […]

Tags

White Papers

The Impact of Concrete Porosity on Flooring Installation

This XLN white paper discusses the significance of ASTM F3191-16, explains the reasons to render a concrete substrate porous prior to the installation of resilient floor coverings, explores the benefits to the installed products, and offers the best method of achieving porosity.

Tags

The Impact of Concrete Porosity on Resilient Flooring Installation

The question has been asked by flooring contractors many times, “Why does the concrete substrate need to be rendered porous prior to the installation of resilient flooring?” Most resilient manufacturers require the substrate to be rendered porous by mechanical means prior to installation. We’ve put together a helpful course deck that: Explains the reasons to […]

Tags

The Impactful Role of Maintenance in Flooring Specification

By Meredith Brown, Regional Architect and Design Manager, Professional Flooring Supply Proper care and maintenance of any product extends its functional life expectancy and ensures the product will perform as desired. Flooring is no exception to this rule. Each type of flooring has its own maintenance guidelines that may become even more specific among each […]

Tags

The Ramifications of Specifications

In this article, XL North’s Bill Luallen, along with Stan Hulin, breaks down the links in the floor care industry chain – from manufacturer to end user. They also discuss one simple, but hard, truth. Although no one along the chain wants to purposefully undermine someone else, it can, and does, happen. Stan and Bill […]

Tags

Thinset Removal Done Right

The team at Southeastern Commercial Flooring recently discovered the dust free benefits of two of XL North’s surface prep products when they were used to remove thinset from a tile and grout demolition. Ken Baxley, SCF Project Manager, discusses the job details. “Our crew was demoing 2”x2” mosaic tile in 4 bathrooms, each approximately 285 […]

Tags

To finish or not to finish LVT floors? That is the question.

In my experience, most Luxury Vinyl Tile (LVT) floors can reach their expected life cycle with very good maintenance practices set in place immediately after the installation. The 1st step in establishing best practices is to become familiar with the manufacturer’s’ maintenance specifications. However, some of them do not include an option for a periodic […]

Tags

Troubleshooting Carpet Cleaning & Maintenance Issues

Often floor care professionals are brought in to clean an area and a first inspection may conclude that the carpet is simply dirty. Or perhaps the carpet has been neglected for awhile and all it needs is a quick extraction to do the trick. However, what has caused the carpet to get to its current […]

Tags

Troubleshooting Hard Surface Floor Care Issues

Troubleshooting resilient floor maintenance issues can be a task because some hard surface floor care issues are difficult to diagnose on first inspection. The aim of this article is to help provide resolutions for a few of these troublesome hard surface problems. As stated in a previous blog article, many artists create paintings with hidden […]

Tags

Case Studies

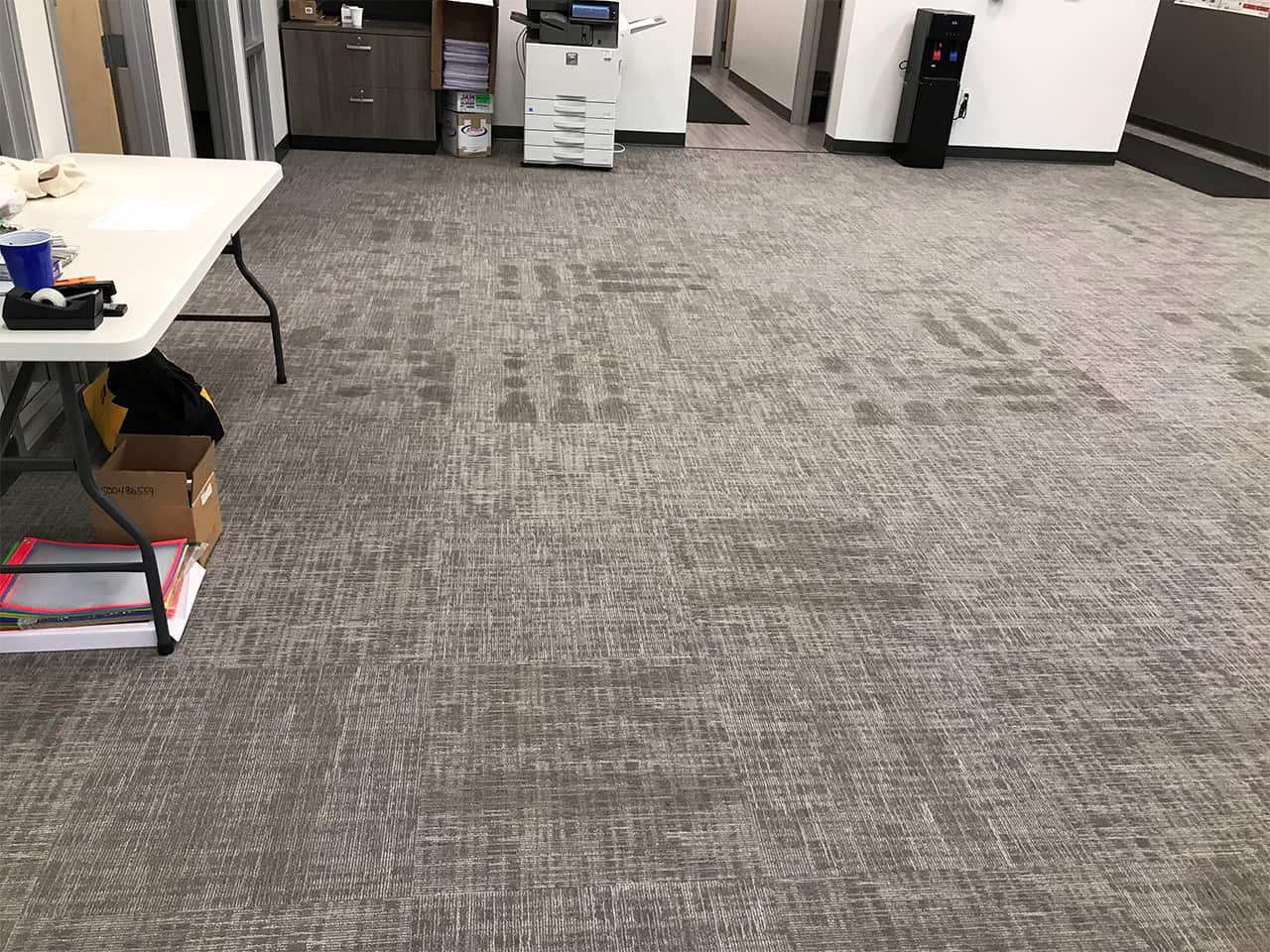

Troubleshooting Line Sputter on Commercial Carpet Tile

Discover the flooring anomaly that could be the source of this unusual soiling situation on commercial carpet tile in this XLN case study.

Tags

Trust the + to Increase Productivity on Concrete Grind and Seal Jobs

A recent concrete grind and seal project in Lower Manhattan provided Peter Criscione, Manager of Hard Surfaces at RD Weis, an excellent opportunity to try XL Porosity+ for the first time. As Peter explains, the 30,000 sq. ft. office space job was different from the start. “Usually we do the floors last, but the client […]

Tags

Case Studies

Vinyl Floor Yellowing Case Study

Steve Starcher, President of Timco in Chicago, was recently called to a hospital, at the request of a manufacturer, to troubleshoot a vinyl floor that had a yellowing problem. In this case study, learn more about the tests that Steve and the Timco team performed on the floor and the ultimate outcome.

Tags

What Causes Discoloration on Resilient Floors?

Written by Rahul Dhavalikar, Director of Product Development, Roppe Holding Company Is something bothering you with the way the resilient floor appears stained or damaged after installation? Is it costing you valuable time and money? With the increasing popularity of resilient flooring in both commercial and residential settings, there has been a rise in inquiries […]