You may be curious why I’ve been posting so much about carpet cleaning processes on LinkedIn, FloorFacts, and now here on XL North’s blog. I’ll explain …

Late last year, industry participants in the Carpet and Rug Institute (CRI) Deep Cleaning Seal of Approval (SOA) program received a letter informing us that a revision to the program was happening and the system was being redefined as:

Deep Cleaning System:

- a cleaning system comprised of a vacuum, solution, and extractor.

CRI Deep Cleaning System SOA Certification Requirements:

- Components must include an SOA-certified vacuum, SOA-certified solution, and SOA-certified extractor.

- An extractor is defined as “a type of cleaning equipment that uses pressure, water/cleaning solution, and suction to extract deeply embedded soil or stains from the carpet.”

As you can imagine, industry peers and I questioned why only water rinse extraction was being allowed to participate in a scientific test to determine levels of soil removal.

Here’s a Little Background

The carpet mills established the CRI over 50 years ago to set standards within the carpet industry. This effort was partly to help them:

- Keep their current customer base, and gain new customers through innovation, new styles, etc.

- Have fewer claims from maintenance issues and poor cleaning.

- Have fewer warranty issues by achieving or surpassing their carpet’s stated performance claims for life of carpet, long-term appearance, stain resistance, etc.

- Enhance environmental and sustainability credentials.

The carpet mills have relied on the CRI to provide accurate, science-based information so they can make informed decisions. Mills know many of their claims come from maintenance and cleaning issues. In response, the CRI established a scientific testing program called the Seal of Approval programs (SOA). These SOA range from vacuum cleaner ratings to solutions testing (chemistry), to extractor ratings, to interim cleaning systems, and then deep cleaning systems (the overall rating of the aforementioned).

Historically, the mills have used the test results when deciding which systems to approve for use on their carpets. Using an approved cleaning system should mean fewer issues for customers and fewer claims for the mills.

Challenges with Current Testing Methods

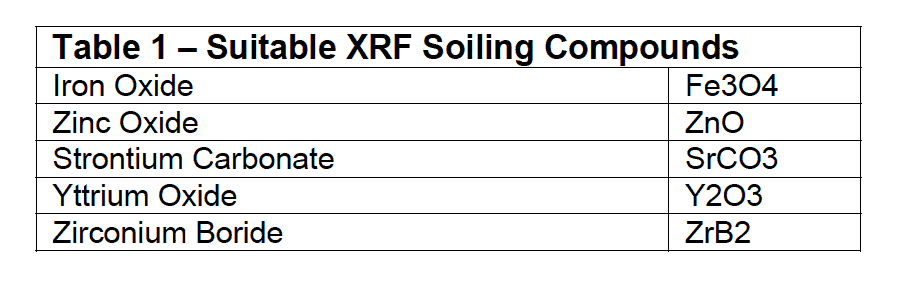

But here lies a problem. The mills assume the CRI is testing for soil removal when certifying a deep cleaning system. The reality is, the CRI is only testing for the removal of five individual components found in different parts of the USA, not actually “soil” itself.

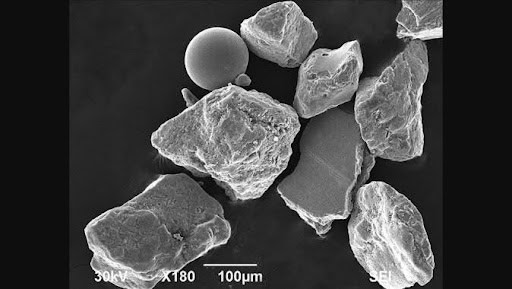

According to the IICRC in its ANSI-accredited S-100 standard, real soil is made of approximately 80% dry particulates and 20% binding agents. The most common dry particulate is silica (about 40%) and it does the most damage to carpet fibers. Surprisingly, silica is not part of the CRI’s ‘soil sample’ used for testing. Along with silica, the CRI testing does not include hair and cellulose material. Like silica, most particulates are insoluble, which means they will not dissolve in water. While these other materials that make up soil may not damage the carpet fiber like silica can, they do provide a good food source for bacteria and mold, which can contribute to air quality issues.

This helps to explain why some approved deep cleaning systems struggle to produce results in real-world situations, and a lower-rated system can do better than a higher-rated system. We believe there is room for improvement.

Why it Matters

But why get so worked up? One of the issues at stake is if you have been servicing your customer and they may be completely happy with the results your cleaning program is providing, but if you say you “Deep Clean” your facility’s carpet once a quarter (or whatever frequency) and you aren’t using a water rinse extraction system, then according to the CRI you are not performing deep cleaning, whether or not the carpet looks great …

We feel that if a system follows the 7 principles of the SOA program which are:

- Soil Removal Efficacy: How effective is the product at removing soil?

- Resoiling: Does the cleaned sample attract soil at an accelerated rate? (cleaning solutions and systems)

- Residual Moisture: Does the extractor or cleaning system remove most of the moisture that results from a wet cleaning process?

- Surface Appearance Change: Does the product leave the carpet minimally changed after multiple cleanings? (vacuums and extractors)

- Colorfastness: Does the product cause a color change in the carpet fiber? (solutions and systems)

- pH Level: Is the pH level between 4 and 10? (solutions and systems)

- Optical Brighteners: Does the product contain optical brighteners? None are allowed for SOA certification.

Then, let the chips fall where they may. If a low moisture cleaning process achieves 83% soil removal, then it’s a gold in the Deep Cleaning SOA. If it doesn’t, then it can’t call itself a deep cleaning system.

Advocating for Low Moisture Carpet Cleaning (LMCC) Systems

Here’s what we think everyone should know about low moisture carpet cleaning systems (LMCC). First off, LMCC can utilize the following processes:

- Dry compound cleaning (absorbent or adsorbent) with agitation using a counter-rotating brush machine (CRB), then vacuuming to remove soil.

- Liquid low moisture encapsulation (spray down) with agitation using a CRB, then vacuuming to remove soil.

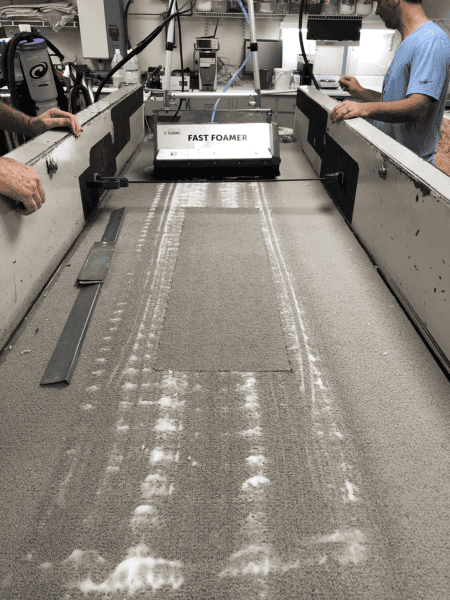

- Liquid low moisture encapsulation (foam application) with agitation using a CRB, then vacuuming to remove soil.

LMCC utilizes significantly less water than water rinse extraction (WRE). This translates to much quicker drying times, often within 20-30 minutes, minimizing disruption to your home or business. Carpets cleaned with WRE can take several hours, up to 8 hours to dry completely, which can be a major inconvenience. Damp carpets are breeding grounds for mold and mildew. The extended drying times associated with WRE increase this risk. LMCC’s minimal moisture use significantly reduces this concern. Most WRE systems rely on a water solution being injected into the carpet pile via a pressured system, a carpet wand, and then the solution is removed immediately out through the carpet wand vacuum slot. LMCC processes use chemistry to release the soils from the carpet fiber and agitation via CRB to bring suspended soils to the surface of the carpet where it is then vacuumed when dried. This process is similar to combing your hair, removing materials without damaging.

With its quick drying times and minimal disruption, LMCC is ideal for busy commercial spaces that can’t afford extended downtime for carpet cleaning. While LMCC offers many advantages, it’s important to acknowledge potential drawbacks. LMCC may not be as effective for greasy/oily soiled carpets such as some restaurants. We have been communicating with the CRI to work on changing the proposed/current CRI Deep Cleaning SOA to include extraction equipment that are non-wet (vacuum cleaner). These have already been tested to not damage the carpet and would remove encapsulated soil from the carpet. This change would give the consumer safe choices to make when deciding what criteria is most important to them.

Call to Action

In today’s world, we have to consider indoor air quality, water and energy consumption, and sound levels when working in our customers’ facilities, and LMCC is a powerful carpet cleaning method that offers faster drying times, reduced mold risk, and a deeper cleaning of real soils. For most all situations, LMCC is an excellent choice. However, for heavily soiled greasy/oil carpets, WRE may still be the preferred method. When choosing a carpet cleaning method, consider the level of soil, carpet type, and drying time requirements to make the best decision for your needs.

As a countdown to Earth Day, I recently published the following posts on LinkedIn. I welcome your perspective and opinion! Your feedback is valuable and can help drive meaningful change in our industry.