Commercial floor care providers know that initial maintenance for resilient flooring is imperative to put the floor in service after construction, but how many have considered post construction carpet cleaning to ready the floor for foot traffic?

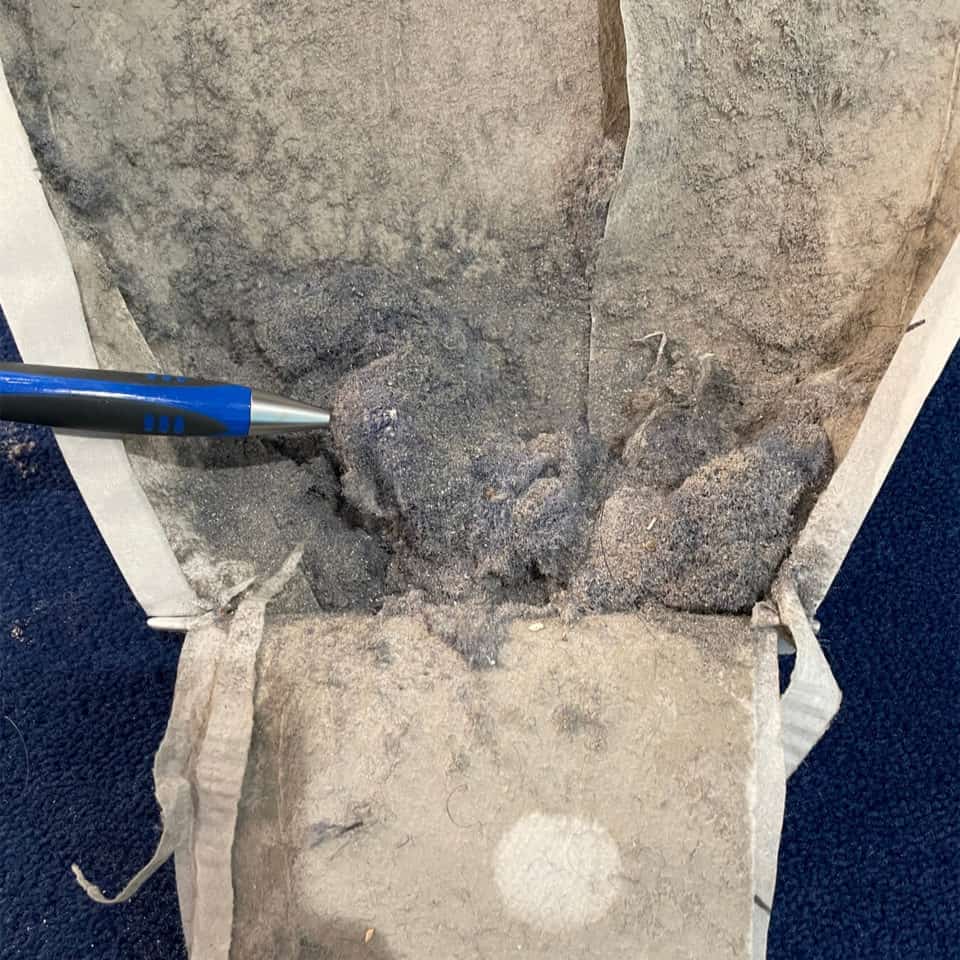

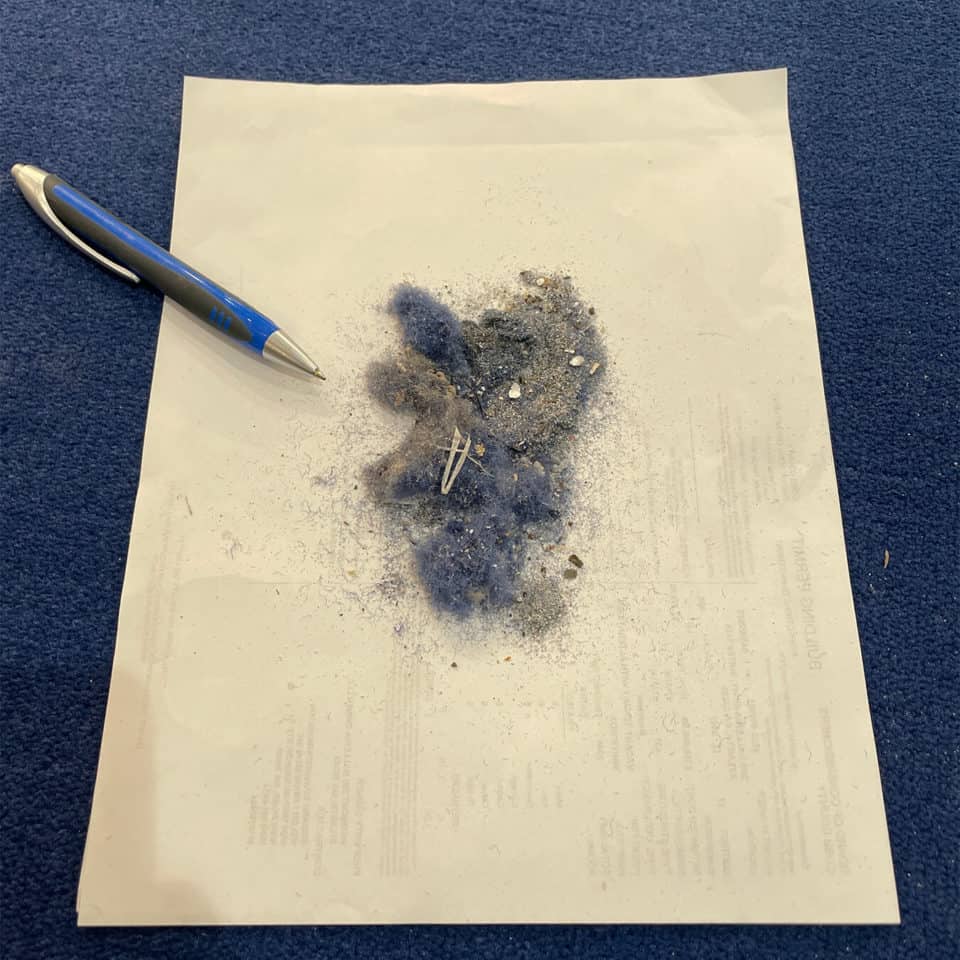

Times have changed and commercial spaces are no longer built top to bottom. Carpet is often installed before other trades have finished their work, and while protecting it from soiling is obvious, it’s not always done properly or successfully. Tracked in dirt along with construction dust and debris may not be visible, even to the professional eye, but a post construction carpet cleaning can be quite revealing. Infinite Floorcare’s Steve Brown shows just how much soil can be removed from newly installed commercial carpet with the proper equipment and process.

Overview & Initial Assessment

Steve was asked by a customer to hot water extract approximately 2,400 square feet of newly installed cut pile commercial carpet. The tenant was concerned about construction debris, and even though the carpet had been vacuumed by the GC, the tenant requested the additional step of having the carpet professionally cleaned.

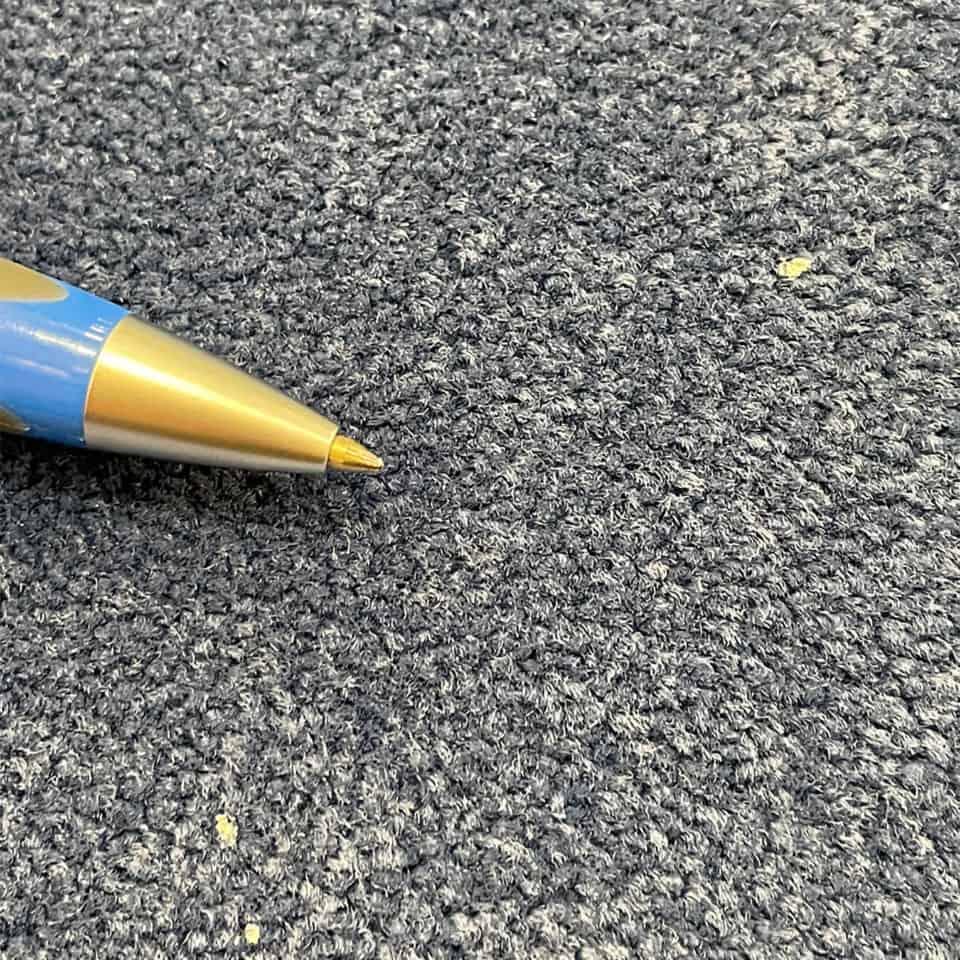

When first assessing the floor, the carpet appeared clean and freshly vacuumed. Steve used a Windsor Versamatic 18 to vacuum the carpet again which revealed several various paint or sheetrock speckles superficially adhered to the face fiber. He laid out a thorough cleaning process to remove the speckles along with any remaining soil and debris.

Cleaning Process

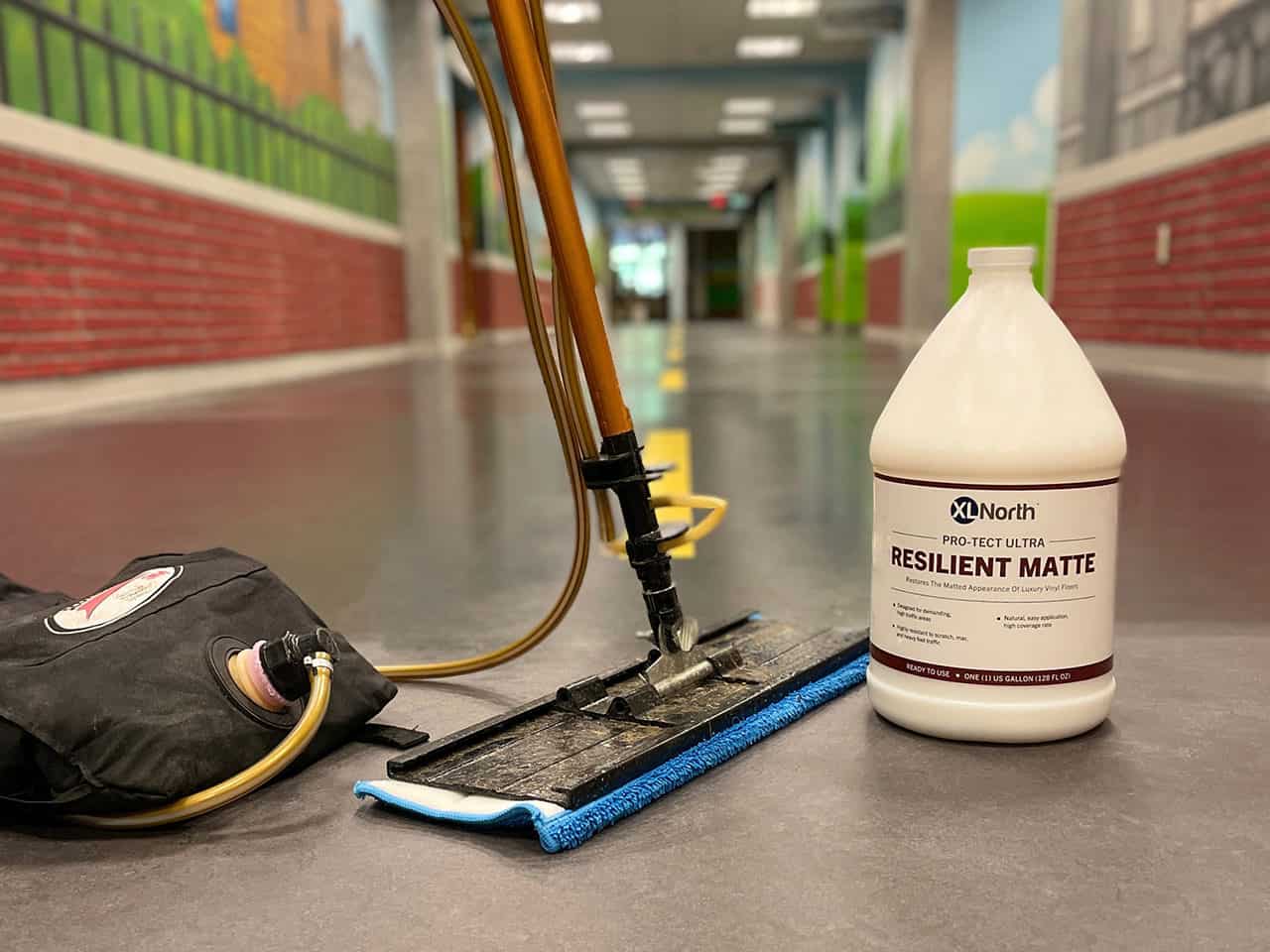

Steve choose not to perform hot water extraction on the newly installed carpet. Why? He explains that because the carpet contained dry construction particulate such as sheetrock dust, the addition of water through hot water extraction could cause it to further solidify and bind to the carpet, making it more difficult to remove. He instead opted to use the Fast Foamer System from Foaming Floors.

Here’s the process followed by the Infinite Floorcare team.

- Vacuumed wall to wall with Windsor Versamatic 18, 3 – 4 passes at approximately 1.8 seconds per square foot, with detail vacuuming along the edges

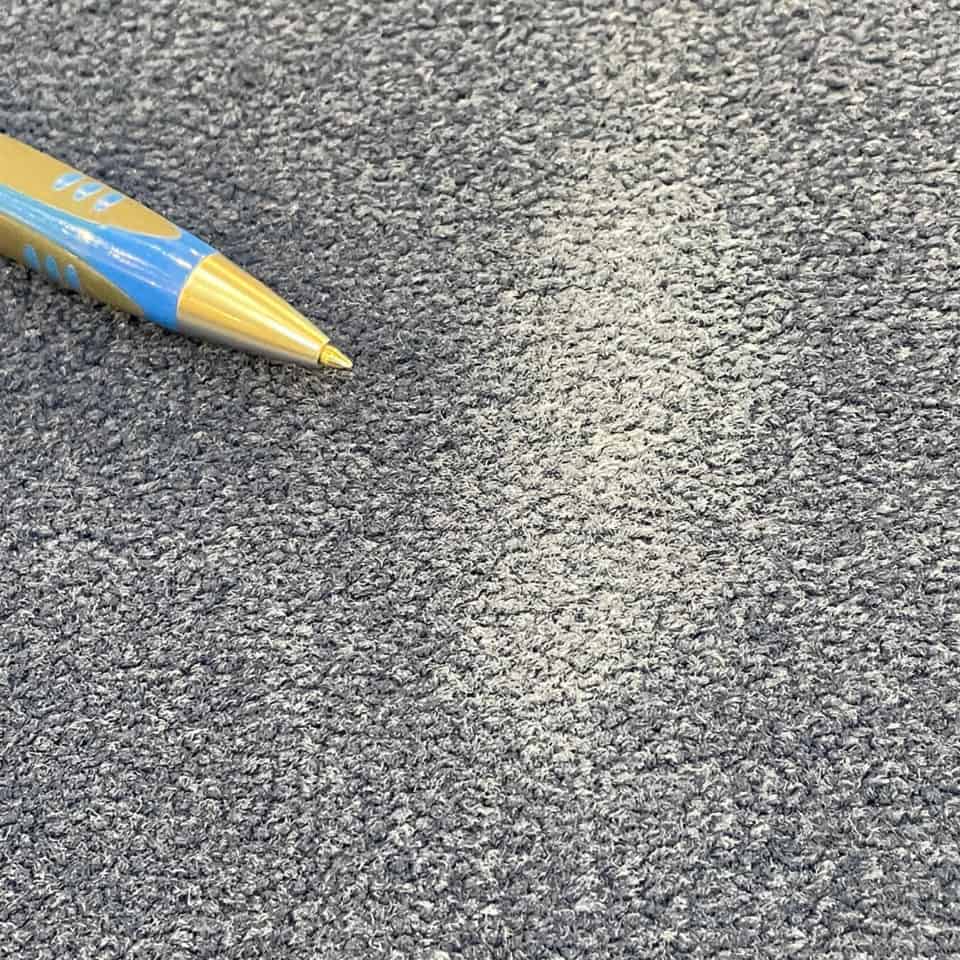

- Used a CRB (Counter Rotating Brush Machine) with appropriate cut pile brush (.17 mm denier), dry with debris collection trays, repeating 3 – 4 passes

- Cleaned carpet using the Fast Foamer System with High Energy Foam with 3 pre-conditioning passes with the CRB, allowing a 5 minute dwell time, and 3 agitation passes in a V pattern

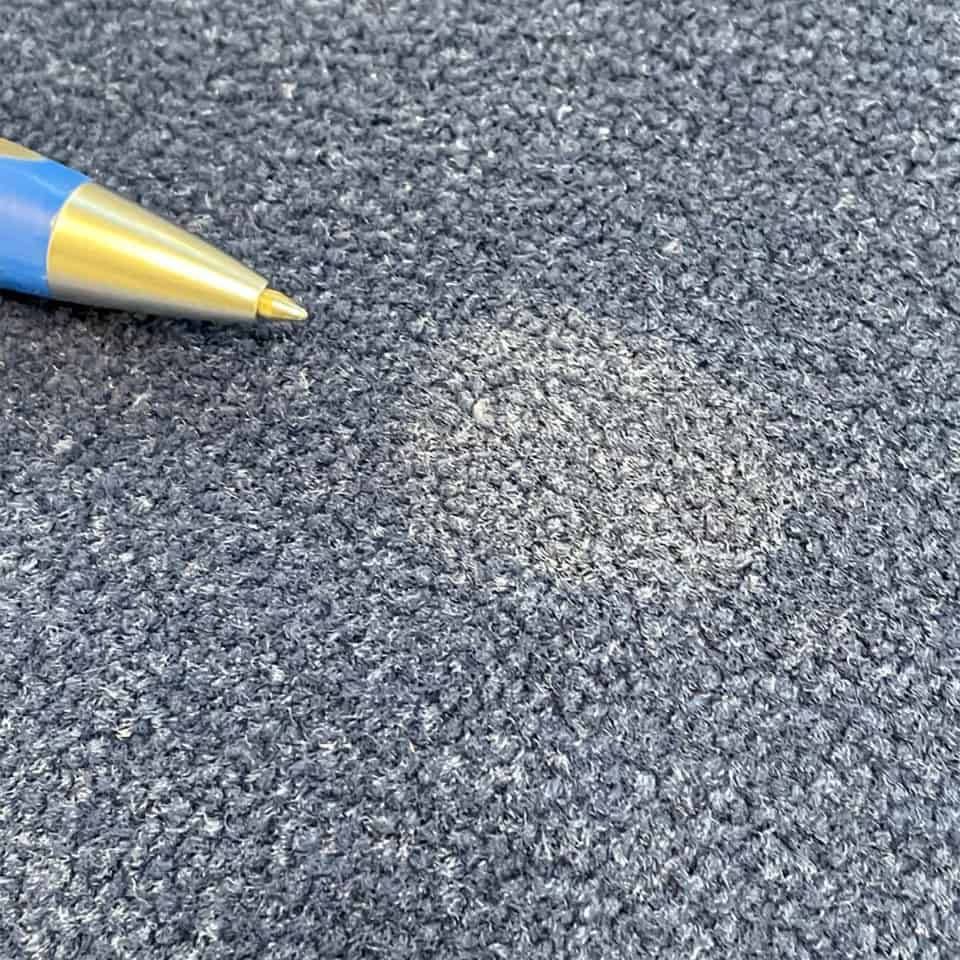

- Any spot or speckle not removed was spot treated with clean terry cloths and XL VDS

Photos

Conclusion

For this post construction cleaning, the commercial grade vacuum cleaner and the CRB machine were an effective combination to remove most of the dry particulate from the carpet. Any remaining soil was then encapsulated through the use of the Fast Foamer System.

In commercial floor care, it’s so important to assess each job individually and utilize the tools that will work best to accomplish the goal. On this job, there was no need to introduce a large amount of moisture to insoluble, dry soil especially when water extraction is not the most effective method for removing it. Although HWE was initially requested by Steve’s customer, they deferred to him based on his professional expertise and were extremely pleased with the outcome of the cleaning process.