XL North is always on the lookout for new advancements in the commercial floor care industry that can help our customers achieve better results. While using foam detergent as a cleaning method has been around for quite some time, the chemistry and process used to create foam has changed greatly over the decades. Recent improvements in technology have made foam a game changer when it comes to cleaning carpet. Here’s why.

Foam enhances the suspension of soils and increases the interfacial tension between the soil and carpet fiber. You can visibly see soils suspended in foam. That alone increases a floor care technician’s cleaning ability and decreases their amount of time needed to clean. Some additional benefits of foam cleaning include:

- Less chemistry needed, reducing pollution

- Decreased drying times

- Less need for thermal energy as foam works with lower water temperatures

To understand foam cleaning, you need to know the science behind the power of foam. You’ve certainly seen foam used at car washes, in your washing machine, and in hand soap. There’s a reason why other cleaning industries have made the switch. Detergents contain surfactants. Surfactant is an acronym for surface active agent, and it’s the component in detergents that’s responsible for the detergent’s ability to remove soil. Surfactants only work at the interface between a liquid and a gas (air) or any hydrophobic (water-resistant) material, such as oil.

So why does foam clean better than a liquid?

With foam, the gas interface is more than 100x that of a liquid. It covers a much greater surface area and exponentially increases the detergent’s effectiveness. Foam is also odorless and eliminates the chemical smell that can occur when detergents are sprayed on carpet in liquid form.

For carpet cleaning, there are a few different foaming systems to choose from, but we’ve found that the Fast Foamer by Foaming Floors is a state-of-the-art system that offers the best process and technology available. Fast Foamer provides a more efficient cleaning process vs. traditional liquid low moisture cleaning by:

- Allowing a more even detergent application method for technicians so there is little to no waste

- Combining the application and agitation steps of carpet cleaning into one process saving time and technician fatigue

- Eliminating water faucet trips by utilizing a larger tank that doesn’t require multiple refills

The Fast Foamer Difference

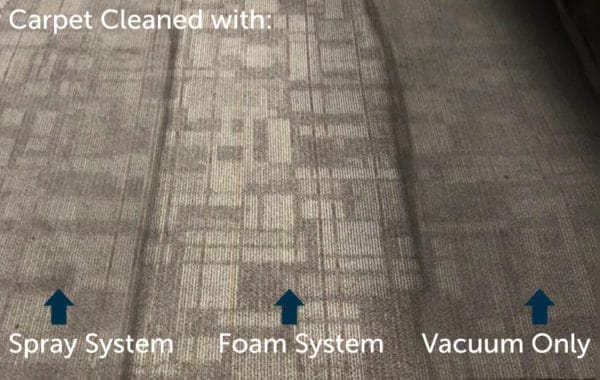

Cleaning was performed using the same Counter Rotating Brush machine with (blue) brushes, same chemistry, dilution ratio (12 oz per gallon), volume of cleaner (600 sq. ft. per gallon) and speed of passes (2 linear feet per second) Two passes each system.

The Fast Foamer is revolutionary in that it utilizes a counter rotating brush machine. This advantage completely differentiates it from other widely available foaming carpet cleaning systems. By combining the efficiency of foam cleaning with the powerful performance of counter rotating brushes, Foaming Floors created a system unlike any other in the marketplace.

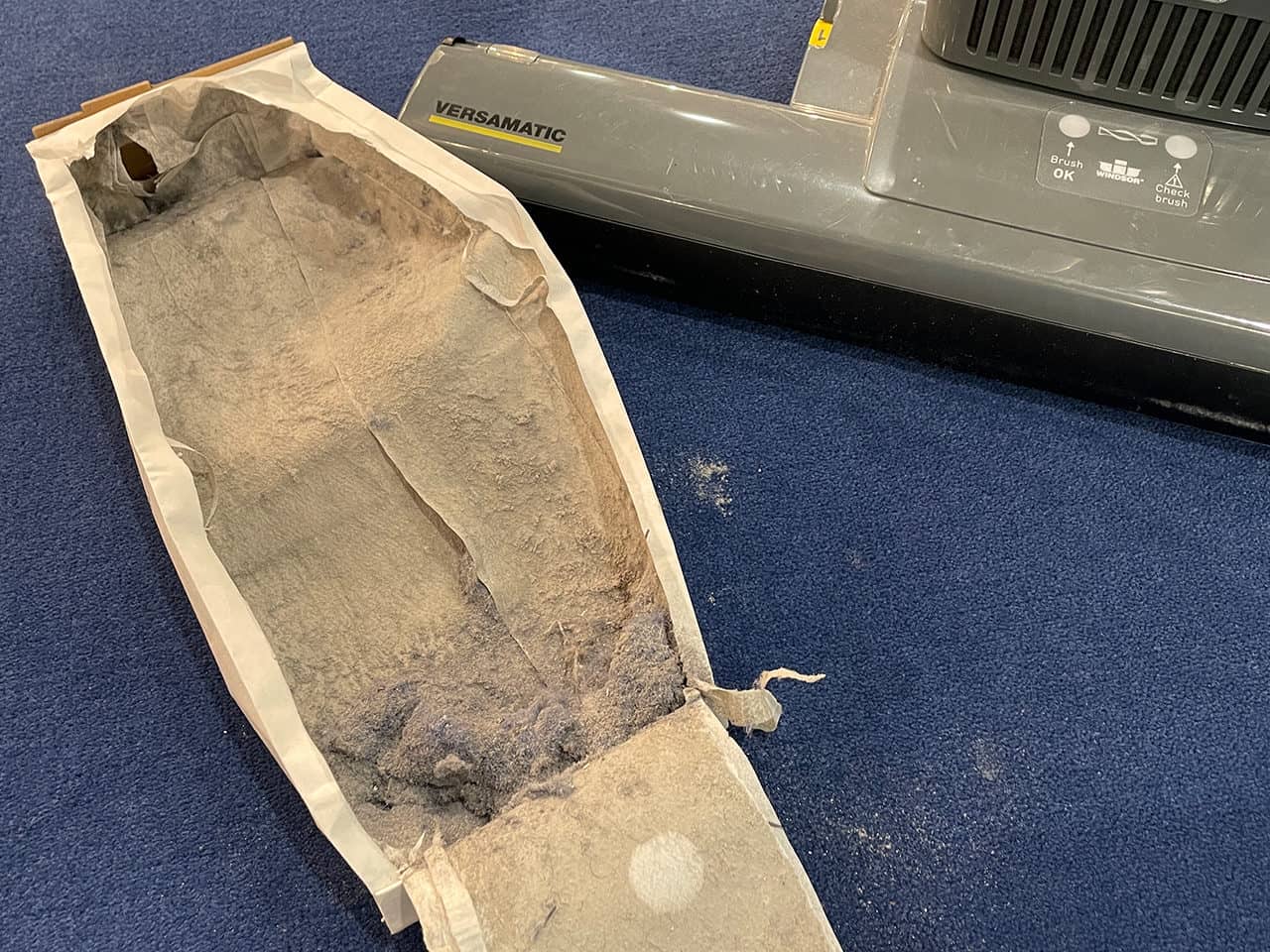

In fact, the Fast Foamer was recently tested by a certified independent laboratory, and the results show that the Foaming Floors system releases twice the amount of soil from the carpet fibers as traditional liquid low moisture systems. Yes, double the soil. What does that mean? Basically, by using the counter rotating brush equipment on the Fast Foamer with the same number of passes, same dwell time, and same volume of chemistry, you can release twice the amount of soil from the carpet fibers with foam than you can by spraying a liquid onto the carpet.

The cutting edge Fast Foamer system bridges the gap between liquid low moisture and hot water extraction, and offers much needed versatility to floor care providers who traditionally required two pieces of equipment for carpet cleaning and maintenance jobs by allowing them to complete the work faster and more effectively with one machine.

To learn more about Foaming Floors and the Fast Foamer system, visit their website today!