Are you familiar with this carpet cleaning scenario? The last snowfall melted a couple of months ago, summer’s here, and your crew is performing second quarter contracted cleaning of local bank branches. At the first location they inspect the facility, bring in equipment, pre-spray, scrub, and extract. They take photos of a job well done and share them with you. Because all looks well, they leave for the next branch location on the list. In the morning, however, calls and emails from upset customers begin. “The carpet cleaning is terrible!” “White stuff is all over the carpet!” The pictures taken by your techs, however, look great with no visible issues. So, what happened? And how do you resolve it? XL North’s Bill Luallen and Timco’s Steve Starcher provide answers and suggestions for combatting this problem year round.

The Issue

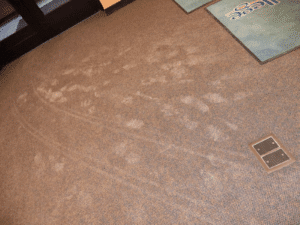

Here’s how the problem arises. Ice melt is spread outdoors over sidewalks and parking lots. It “walks” into a building on the bottoms of shoes. Once indoors, regardless of whether it’s in solid or dissolved state, the ice melt finds a cozy spot on the carpet. It’s repeatedly walked on and pushed to the base of the flooring. As the wet carpet dries, the customer may see some “white haze” or salt residue on the carpet. Vacuuming usually fixes it. However, weeks or months later when your maintenance crew comes in with water extraction equipment, science takes over, and the problem is literally brought to the surface.

The Science

So why not use low moisture encapsulation chemistry? Will that work? Bill’s answer is yes and no. He explains, “It will capture the salt that may be on the surface, but it won’t remove the salt that is at the base of the carpet, and without removing that, your customer will continue to be an issue.”

The Solution

How do you resolve ice melt issues? During the winter months, use our handy set of suggested procedures to keep problems to a minimum. One best practice during colder months is to deep clean the building entrances to eliminate heavy salt buildup. Throughout the rest of the year, Steve and Bill recommend talking with your customers, educating them on the principals of cleaning, and helping them understand the physics of capillary action (wicking). Steve notes, “If you have this conversation and deliver results, the customer sees the cost of neglect through the winter months.” It’s an opportunity, as he points out, to sell them on maintenance services that can be beneficial throughout winter. Bill also advises sending down draft fans with your crews to accelerate the wicking process so they can see any potential ice melt issues before your customers do. Additionally, Steve asks, “Has the customer mentioned any slippage problems in entrance areas that aren’t carpet?” If so, it’s an opportunity to scrub the floor and remove ice melt residue that’s formed on that surface as well. Finally, if the issue is specific just to walk off mats, Steve recommends moving the mats off site. “If the mats can be cleaned off site, you can use multiple extractions and save in drive time and cost.” He notes, “Polypropylene fiber can be very difficult to deal with, and it’s hard to know how much ice melt compound was tracked into the matting.”

Trust that, like winter, ice melt issues are coming. Combat it by keeping your techs informed and ensuring they’re performing at their best.